| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Atlas

Model Number : GA 37 VSD+

Certification : ISO 8573-1 CLASS 0

Place of Origin : China

MOQ : 5

Price : negotiable

Payment Terms : T/T, Western Union

Supply Ability : 1000 pcs per month

Delivery Time : 7-30 days

Packaging Details : as atlas corp standard

Material : Aluminum Alloy

Model : GA 37 VSD+

Type : Frequency Conversion

Brand : Atlas Copco

Power : 37kw

Motor : Interior Permanent Magnet

Atlas Copco Ga Vsd+37 Oil-Injected Rotary Screw Air Compressor

specifications

| Compressor type | Max. working pressure | Capacity FAD* (min-max) | Installed motor power | Noise level** | Weight WorkPlace | Weight WorkPlace Full Feature | ||||

| GA 37 VSD+ | bar(e) | psig | l/s | m³/h | cfm | kW | hp | dB(A) | kg | kg |

| 4 | 58 | 15-116 | 55-419 | 32-246 | 37 | 50 | 67 | 376 | 500 | |

| 7 | 102 | 15-115 | 53-413 | 31-243 | 37 | 50 | 67 | 376 | 500 | |

| 9.5 | 138 | 17-102 | 62-368 | 36-216 | 37 | 50 | 67 | 376 | 500 | |

| 12.5 | 181 | 16-87 | 59-312 | 35-183 | 37 | 50 | 67 | 376 | 500 | |

Why Atlas Copco Variable Speed Drive + technology?

• On average 50% energy savings with an extensive flow range (20-100%).

• Integrated Elektronikon ® Touch controller controls the motor speed and high-efficiency frequency inverter.

• No wasted idling times or blow-off losses during operation.

• Compressor can start/stop under full system pressure without the need to unload.

• Eliminates peak current penalty during start-up.

• Minimizes system leakage due to a lower system pressure.

• EMC compliance to directives (2004/108/EG).

* Compared to fixed speed compressors, based on measurement performed by an independent energy audit agency.

The New Revolutionary Compressor From Atlas Copco GA90 VSD+

Innovative

Atlas Copco has revolutionized compressor build and performance. Instead of the normalspace-taking horizontal design, the new

GA 37-110 VSD + has an upright, compact layout. This saves valuable floor and work space, eases maintenance access, and reduces the total cost of ownership for all customers.

Reliable

• Our Neos inverter, developed in-house to maximize compressor reliability, is built to provide extra protection against dust and other particles.

• Completely enclosed frequency drive and drive train ensure performance even in the harshest environments.

• Based on the unique combination of proven technologies and existing components, optimally brought together by Atlas Copco’s experience and know-how.

Smart

• Easy monitoring and maintenance thanks to the Elektronikon ® Touch controller.

• Maintenance notifications and machine status are available via SMARTLINK e-mail or text messages.

• Customized reports on the energy performance of your machine, in compliance with ISO 50001.

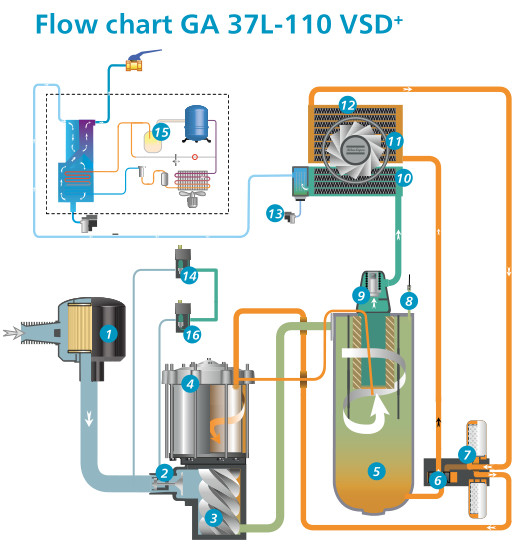

1

Interior Permanent Magnet (iPM) motor

• Oil-cooled motor.

• Optimal cooling for all speeds and ambient conditions.

• Designed in-house in Belgium.

• Oil-lubricated motor bearing: no (re)grease(ing), increased

uptime.

• IP66: pressure tight.

• Permanent magnets.

2

New compressor element

• New improved rotor profile.

• Reduced pressure losses.

• Optimized in and outlet portals.

3

Direct drive

• Vertical design, less parts.

• Oil-cooled, pressure-tight.

• No gears or belts, no shaft seal.

4

Inlet filter

• Heavy duty.

• Maintenance every 4,000 hours.

• Pressure drop indicator.

5

Radial fan

• Compact.

• Low noise level.

• High capacity for optimized cooling.

6

Classic cooler design

• Integrated water separation.

• Separate oil/air cooler.

• Easy access for maintenance.

7

Innovative Neos inverter

• Atlas Copco’s in-house designed inverter now also controls iPM motors.

• IP5x protection.

• Robust aluminum enclosure for trouble-free operation in the harshest conditions.

• Fewer components: compact, simple and user-friendly.

8

Integrated dryer

• Extra compact footprint.

• Refrigerant R410A.

9

Elektronikon ®

Touch controller

• High-tech controller with warning indications, compressor shut-down and maintenance scheduling.

• Easy to use and designed to perform in the toughest conditions.

• Standard SMARTLINK remote monitoring to maximize air system performance and energy savings.

• Optional multiple compressor control (2, 4 or 6 compressors).

10

Sentinel valve

• Optimizes the inlet flow of the air end.

• No blow-off losses.

• Full aluminum design: maintenance-free.

11

VSD + Neos cubicle

• VSD + is superior to idling machines.

• Electrical components remain cool, enhancing their lifetime.

• Dedicated drive for iPM technology motors.

• Heat dissipation of inverter in separate compartment.

|

|

Multipurpose Low Pressure Compressor , 37KW Oil Injected Screw Air Compressor Images |